For Lyman High, the addition of XLT conveyor ovens and an XLT hood has revolutionized their kitchen operations.

At Lyman High School in Longwood, Florida, feeding 1,400 hungry students every day is no small task. But thanks to the innovative technology of XLT 3255 ovens and the XLT Hood, lunchtime is now efficient, stress-free, and even enjoyable. Partnering with Red Apple Dining, the high school serves hot, fresh pizzas and nutritious meals in record time, all while keeping the kitchen as cool as a cucumber.

High Efficiency Meets High Volume

With over 75 years of experience, Red Apple Dining is committed to delivering high-quality, USDA-compliant meals to Seminole County students. At Lyman High, this means serving 700 students in just 15 minutes—twice a day! Such a feat might sound impossible, but the XLT 3255 conveyor ovens make it look easy.

Here’s how they do it:

- Rapid Bake Times: The XLT conveyor pizza oven ensures that every pizza is perfectly baked in minutes, allowing the team to meet the fast-paced demands of high school lunch periods.

- Consistent Results: The conveyorized impingement oven technology delivers even heat, ensuring every slice of pizza meets the same high-quality standard, no matter how busy the kitchen gets.

- Cool and Comfortable Kitchens: With the addition of the XLT Hood and its capture and contain ventilation system, Lyman High’s kitchen stays cool under pressure. Gone are the days of kitchens turning into saunas during peak hours.

Nutritious and Delicious: A Winning Combination

Beyond speed and efficiency, Red Apple Dining ensures every meal is as nutritious as it is delicious. Their menu features:

- More whole grains

- Reduced sodium and sugar

- Healthier milk options

This commitment to nutrition helps meet USDA standards while making healthy eating appealing to even the pickiest teenagers.

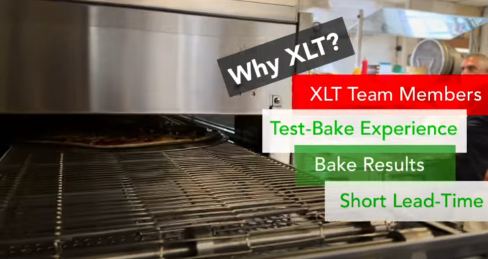

Transform Your School’s Kitchen with XLT

For Lyman High, the addition of XLT conveyor ovens and hoods has revolutionized their kitchen operations. The team no longer worries about long prep times, overheating, or inconsistent results. Instead, they can focus on what truly matters: serving meals that bring smiles to students’ faces.

If you’re ready to make lunchtime at your school stress-free and efficient, it’s time to bring XLT ovens and ventilation systems into your kitchen. From perfectly baked pizzas to a cooler, more comfortable workspace, XLT offers the solutions you need to succeed.

Contact XLT Today

Want to learn more about how the XLT 3255 conveyor impingement ovens and capture and contain ventilation systems that can transform your school’s kitchen? Call us today to get started learning more about how the XLT 3255 conveyor pizza oven can bring efficiency, consistency, and happiness to your kitchen. Contact: sales@xltovens.com or (316) 943-2751