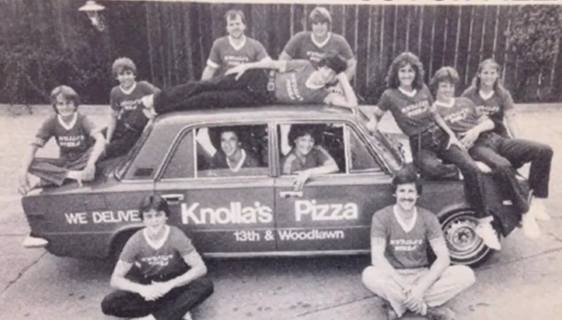

Flashback: The Knolla’s Pizza Team, circa 19??

For over 40 years, Knolla’s Pizza has been serving up delicious, mouth-watering pizzas to the Wichita, Kansas community. Known for their signature New York-style and Chicago deep-dish crusts, Knolla’s piles on fresh toppings, gooey cheese, and savory sauce. With the help of XLT conveyor ovens, they ensure each pizza is cooked to perfection—quickly, consistently, and deliciously.

A Slice of History

The journey of Knolla’s Pizza began back in 1979 when the Knolla brothers, Pat and Tim, left corporate pizza jobs to pursue their dream of creating the perfect pizza. They headed to New York City to learn from the best, before opening their first location in Orlando, Florida. Soon after, they moved to Wichita, where they established Knolla’s Pizza and quickly gained a loyal following. Today, the Knolla family continues to run Knolla’s locations throughout Wichita, maintaining their commitment to quality and community.

Why Knolla’s Chose XLT Ovens

Knolla’s is renowned not only for its fresh ingredients but also for its perfectly cooked pizzas. Achieving this level of consistency and speed is no easy feat, especially with the high volume of orders they receive. That’s why Knolla’s uses XLT conveyor ovens in its kitchens. These ovens are equipped with advanced impingement oven technology, which allows them to produce pizzas that are crispy on the outside, soft on the inside, and full of flavor.

Benefits of XLT Conveyor Pizza Ovens

- Faster Cooking Times: With XLT conveyorized impingement ovens, Knolla’s can cook pizzas faster without compromising quality. The air impingement technology speeds up cooking by circulating hot air around the pizza, allowing each pizza to bake in just minutes.

- Consistent Quality: XLT ovens are designed for consistency, ensuring every pizza comes out with the same delicious, even bake. Whether it’s a classic cheese pizza or a loaded Chicago deep dish, Knolla’s can depend on the XLT conveyor system to deliver a perfect bake every time.

- Ease of Use: With the conveyor oven’s automated system, staff members can simply place the pizza on one end, and it comes out fully baked on the other. This ease of use has made it possible for Knolla’s team to focus on what they do best: creating pizzas topped with fresh, high-quality ingredients.

Supporting the Community with Every Slice

For the Knolla family, pizza is more than just food—it’s a way to connect with the Wichita community. The loyalty of Knolla’s customers, many of whom they know by name, is a testament to their commitment to quality and service. By investing in XLT conveyor ovens, Knolla’s can serve more customers efficiently, especially during peak times, without sacrificing the quality that made them a Wichita favorite.

Experience the XLT Difference at Knolla’s Pizza

When it comes to making great pizza, having the right equipment is key. Knolla’s Pizza shows how XLT conveyorized impingement ovens can enhance not only the quality of the pizza but also the overall experience for both customers and staff. So, the next time you’re in Wichita and craving a heavenly slice of New York or Chicago-style pizza, head over to Knolla’s Pizza, where every pizza is made with love and baked to perfection in an XLT oven.