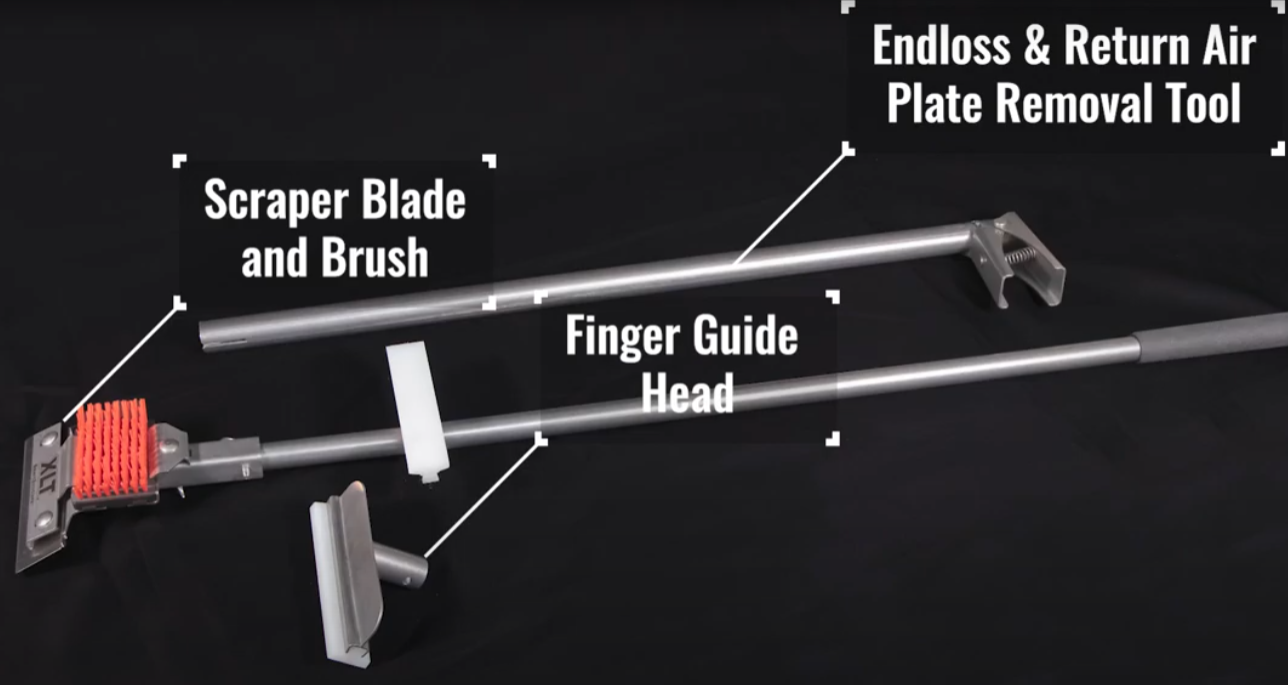

The XLT Cleaning Tool is engineered for user-friendliness, allowing kitchen staff to perform oven cleaning tasks with minimal effort

Introduction to XLT’s Cleaning Tool

XLT Ovens has developed a specialized cleaning tool designed to simplify the maintenance and cleaning of conveyor ovens. This innovation addresses the common challenges faced by commercial kitchens in maintaining cleanliness and efficiency while using conveyor ovens.

Ease of Use

The XLT Cleaning Tool is engineered for user-friendliness, allowing kitchen staff to perform oven cleaning tasks with minimal effort. Its ergonomic design ensures that it can be handled comfortably, reducing strain while performing cleaning procedures. The tool’s straightforward operation makes it accessible to all employees, promoting consistent cleaning practices with all kitchen staff.

Efficiency in Cleaning

One of the standout advantages of this cleaning tool is its ability to save time. Traditional cleaning methods can be laborious and time-consuming, often requiring multiple tools and extensive manual labor. XLT’s Cleaning Tool streamlines this process, enabling users to clean conveyor ovens more quickly and effectively. This efficiency not only enhances productivity but also allows kitchen operations to maintain a higher standard of cleanliness with less downtime.

Durability and Effectiveness

Constructed from high-quality materials, the XLT Cleaning Tool is built to withstand the rigors of daily use in a bustling kitchen environment. Its robust design ensures longevity, making it a cost-effective investment for your kitchen. Additionally, the tool’s effectiveness is demonstrated through its ability to remove stubborn residues and build-up, ensuring that ovens operate at peak performance without compromising food safety.

Safety Features

Safety is a priority in any kitchen setting, and XLT has integrated several safety features into the Cleaning Tool. The design minimizes the risk of injury, with rounded edges and a non-slip grip that helps prevent accidents during use. Furthermore, the cleaning tool is easy to clean itself, preventing cross-contamination.

XLT’s Cleaning Tool represents a significant advancement in the maintenance of conveyor ovens. By prioritizing ease of use, efficiency, durability, and safety, XLT Ovens has created a product that meets the demands of modern kitchens. This tool not only simplifies cleaning processes but also contributes to a safer and more hygienic cooking environment.