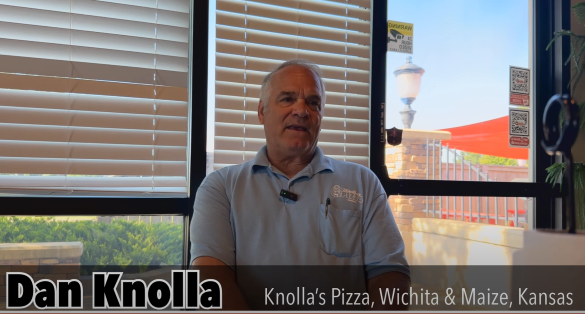

Dan Knolla talks about his experience with deck ovens.

In the world of pizza-making, oven technology has come a long way. From traditional Blodgette deck ovens with their hot spots and constant supervision to modern XLT conveyor ovens, the shift has transformed kitchen operations. The Knolla’s Pizza’s journey from Blodgette to XLT ovens showcases how upgrading to a conveyorized impingement oven can simplify the baking process, improve consistency, and enhance efficiency.

The Challenges of Traditional Deck Ovens

Dan Knolla explains that back in the day, pizza shops relied heavily on deck ovens like the Blodgette. While these ovens had their charm, they also had significant drawbacks:

- Constant Supervision: Deck ovens required an operator to be present at all times, managing hot spots and rotating pizzas to ensure even baking.

- Heat Inefficiency: Deck ovens often had uneven heating zones, which could lead to inconsistent baking results.

- Labor-Intensive Operation: Managing a deck oven took skill, experience, and physical effort, making it challenging for busy kitchens to keep up with high demand.

For Knolla’s, switching to XLT conveyor ovens marked a significant upgrade, solving many of these issues.

Why XLT Conveyorized Impingement Ovens Are a Game-Changer

- Ease of Use: XLT conveyor pizza ovens make baking simple. Operators place the pizza on one end of the conveyor, and it emerges perfectly baked on the other side. There’s no need to constantly monitor or rotate the pizzas, making it easier for staff to manage high volumes.

- Consistent Quality: Unlike traditional deck ovens, impingement ovens use streams of hot air to ensure even heat distribution. This results in pizzas with uniform crusts and perfectly melted toppings, every time.

- Reliability and Minimal Maintenance: XLT ovens are known for their durability and low maintenance. In fact, this pizzeria reports only a handful of service calls in over 20 years—an impressive track record that speaks to the quality of XLT conveyor ovens.

- Efficiency for High-Volume Kitchens: For pizzerias handling large orders, speed is essential. The conveyorized impingement oven technology in XLT ovens enables faster cooking times, allowing restaurants to keep up with demand without compromising on quality.

A Modern Solution for Today’s Pizzerias

Making the Switch to XLT ovens has brought this pizzeria’s operations into the modern age. By eliminating the constant need to monitor and rotate pizzas, these ovens have streamlined workflows, reduced labor demands, and improved the consistency of each bake. No longer do operators need to worry about hot spots or burnt crusts; XLT’s conveyor ovens ensure a perfect bake, every time.

For any pizzeria still relying on traditional deck ovens, making the switch to an XLT conveyor pizza oven, like Knolla’s Pizza did, could be a game-changer. With minimal maintenance, superior efficiency, and a consistently high-quality bake, XLT ovens offer a reliable and effective solution for today’s high-volume pizza kitchens.