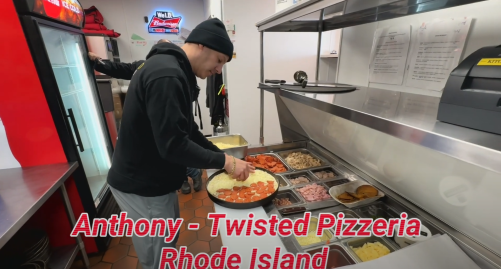

Customer: Twisted Pizza

"The switch to XLT ovens was a no-brainer. The product is exactly the same, and we can do it in half the time."

Case Study: Twisted Pizza's Success with XLT Ovens

Location: Providence, Rhode Island

Owner: Anthony Lopez

Background

Twisted Pizza is a family-run pizza chain rooted in over 50 years of tradition. Originally launched by the Filippou family as Filippou’s Pizza, Twisted Pizza was born when Steve Filippou, Anthony’s brother-in-law, put his own "twist" on the family business. A few months later, Anthony and his wife Effie opened their own pizzeria, Effie Filippou’s Twisted Pizza. Together, the couple diversified the menu, adding items like burgers, fajitas, and specialty wings to accompany the original pizzas.

With growing success, Twisted Pizza evolved from a single location into a small franchise, each offering a full-service dining experience with liquor licenses and expanded menu options. As business grew, so did the challenges of keeping up with increasing customer demands, especially on busy nights.

Challenges

Anthony and his team were facing operational bottlenecks as demand surged, especially during peak times on Friday and Saturday nights. Twisted Pizza's original kitchen setup featured double-deck stone ovens, which required significant skill and time to manage. On busy evenings, up to 40 pizzas would be waiting to bake, causing delays and limiting their ability to meet customer demand efficiently.

As Anthony described, "We were at our max capacity...you can only make 250 pizzas on a Friday, and customers were waiting 45 minutes to an hour for their orders." This was a serious challenge, as longer waiting times could lead customers to go elsewhere. The stone ovens, while traditional, were proving inefficient and difficult to operate at scale.

Solution: XLT Conveyor Ovens

Faced with increasing demand and the need to improve operational efficiency, Anthony turned to XLT conveyor ovens, which offered the promise of faster cooking times, consistency, and ease of use. After consulting with Marco at North American Restaurant Equipment, who recommended the XLT ovens, Twisted Pizza decided to make the switch.

XLT ovens delivered immediate results:

- Reduced Cook Times: The cooking time for pizzas dropped significantly, from 17-20 minutes in the stone ovens to just 7 minutes with the XLT ovens. “Now we can tell customers their pizza will be ready in 25 minutes, instead of 45 minutes to an hour,” Anthony said.

- Consistency: The conveyor ovens provided a consistent cook, ensuring every pizza came out evenly cooked, with perfectly toasted cheese and crisp crusts. Anthony noted, “The product that comes out is the same, every time. No more worrying about one pizza being undercooked or burned.”

- Ease of Use: Unlike the stone ovens, which required skilled operators to manage, the XLT ovens allowed any staff member to cook pizzas with the same quality results. “Training new team members is so much easier now. You just put the pizza in, and it comes out perfect every time,” Anthony shared.

Key Benefits of XLT Ovens for Twisted Pizza

- Increased Efficiency: The switch to XLT ovens drastically improved the kitchen’s ability to handle high volumes of orders during peak times, allowing Twisted Pizza to serve more customers faster.

Improved Customer Experience: Faster service times reduced customer wait times, creating a better dining experience and helping to retain loyal patrons. “When you can tell someone they can get their pizza in 10 minutes, they stay,” said Anthony. - Operational Simplicity: The ease of cleaning and maintaining the XLT ovens was another major advantage. The ovens were designed to be disassembled quickly for cleaning, reducing downtime and eliminating the need for specialized technicians. “These ovens are so easy to clean, it doesn’t make sense to hire someone else to do it,” Anthony explained.

- Product Consistency: With the conveyor system, Twisted Pizza achieved a level of consistency that was previously impossible with the stone ovens. This consistency was critical in maintaining the high quality of their award-winning pizzas, especially during high-demand times.

Results

Since installing XLT conveyor ovens, Twisted Pizza has been able to handle their growing demand without sacrificing product quality or customer service. The ovens have allowed Anthony and his team to scale their operations and keep up with the rush, particularly on busy nights.

Despite initial concerns about moving away from the traditional stone ovens, Anthony quickly realized that XLT ovens delivered the same quality product while drastically improving efficiency. Twisted Pizza has continued to win awards, including “Best Pizza in Rhode Island” for several consecutive years, proving that the switch to XLT ovens was a smart choice.

In Anthony’s own words, “The switch to XLT ovens was a no-brainer. The product is exactly the same, and we can do it in half the time. The customers don’t notice any difference, but we notice the ease of operation and the boost in efficiency.”