"I spent more time with XLT, and they spent more time with me. Their team helped me dial in the exact temperature and consistency I wanted."

Case Study: Bordenaro’s Pizza – Elevating Tradition with XLT Ovens

Customer: Bordenaro’s Pizza

Location: Des Moines, Iowa

Owner: Chris Bordenaro

Background

For over 45 years, Bordenaro’s Pizza has been a cornerstone of the Des Moines, Iowa, community, serving up high-quality, handmade pizzas. Originally founded by Chris Bordenaro’s father in 1977, the restaurant has built a strong reputation for its commitment to tradition and great flavor.

After decades of using traditional deck ovens, Bordenaro’s faced increasing challenges with aging equipment, labor-intensive processes, and rising customer demand. Seeking a modern yet reliable solution, owner Chris Bordenaro made the strategic decision to transition to XLT conveyor ovens and hoods, significantly improving efficiency, consistency, and ease of operation.

The Challenge: Aging Equipment & Operational Bottlenecks

For years, Bordenaro’s relied on Blodgett deck ovens, some of which were over 50 years old. While these ovens produced the classic pizza style customers loved, they presented a growing set of challenges:

- Longer Bake Times – While pizzas started with a 12-minute bake time, heavy volume and frequent door openings extended cook times up to 20–25 minutes on busy nights.

- Labor-Intensive Process – Managing the ovens required a two-person team: one constantly rotating and repositioning pizzas for even cooking, and the other handling slicing and boxing.

- Equipment Downtime & Repair Issues – Replacement parts for the old ovens were difficult to source, and any breakdown resulted in week-long delays waiting for repairs.

- Inconsistent Cooking – Hotspots and fluctuating temperatures meant pizzas required constant monitoring, which put immense pressure on the most experienced staff members.

- High Stress & Limited Flexibility – Chris and his long-time team members were locked into working every Friday and Saturday night, ensuring oven consistency.

“We were constantly spinning pizzas, moving them around, finding the right hot spots—it was exhausting. If I could have done this 20 years ago, I would have.”

– Chris Bordenaro, Owner, Bordenaro’s Pizza

The Solution: XLT Conveyor Ovens & Ventilation

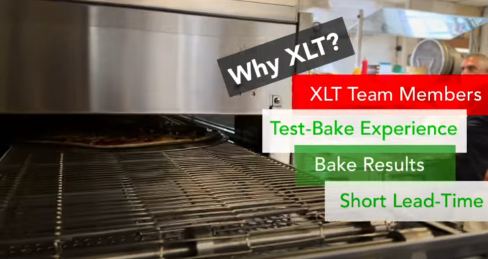

Chris knew he needed a better system. He test-marketed two major oven manufacturers, ultimately choosing XLT Ovens for their superior customer support, consistency, and ease of use.

“I spent more time with XLT, and they spent more time with me. Their team helped me dial in the exact temperature and consistency I wanted.” – Chris Bordenaro

By switching to XLT, Bordenaro’s was able to eliminate inefficiencies while maintaining the same high-quality pizza their customers expected. The benefits were immediate:

- Faster, More Consistent Bake Times – With XLT’s conveyor system, bake times are standardized, eliminating fluctuations caused by door openings.

- Reduced Labor Costs – The new ovens cut down the need for two employees managing the deck ovens, freeing up staff for other tasks.

- Simplified Training & Operation – Unlike deck ovens that require extensive experience, the XLT ovens allow any employee to achieve the perfect bake every time.

- Reliable Performance & Easier Maintenance – No more waiting on rare parts—XLT ovens are built for efficiency and minimal downtime.

- Cooler, More Comfortable Kitchen – The new ovens reduce excess heat output, creating a more comfortable working environment.

“Now, anyone can work the oven—you just put the pizza in, and it comes out perfect on the other… …Now, I can take a night off.”

Results: Transforming Bordenaro’s Pizza for the Future

Since upgrading to XLT conveyor ovens and hoods, Bordenaro’s has seen remarkable improvements in both operations and quality.

- Consistent, High-Quality Pizzas – Every pizza now has the signature crispy crust customers love, without the hassle of constant rotation.

- Increased Efficiency – The team can push out hundreds of pizzas per night without bake time slowdowns.

- Work-Life Balance for Ownership – Chris and his long-time manager can finally take nights off, knowing the ovens will deliver consistent results.

- Scalability for the Future – With easier training and lower labor dependency, Bordenaro’s is better positioned to expand operations in the coming years.