“Before, nothing ever came out of those [old ovens] done. Now, everything comes out consistent. I don’t even have to babysit the pizzas anymore.”

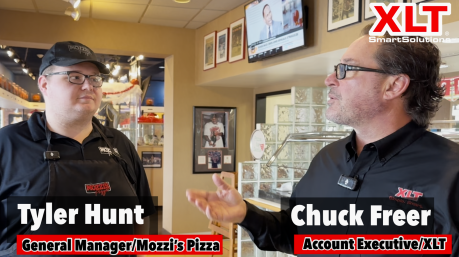

Case Study: Mozzi’s Pizza - Making the Switch to XLT Ovens

Customer: Mozzi’s Pizza

Location: Indianapolis, Indiana

Team Members: Bryan, Rob, Tyler

Partner: Deven Kaufman, C&T Design

Background

Mozzi’s Pizza, a well-established name in the Indianapolis, IN area, has been serving its loyal customers for decades. With multiple locations, they faced a growing challenge — outdated deck ovens that were slow, labor-intensive, and inconsistent. To maintain quality, improve efficiency, and expand their capabilities, Mozzi’s Pizza decided to Make the Switch to XLT Conveyor Ovens and XLT Hoods. The results? A game-changer for their business.

Challenges: Outdated Equipment Slowing Growth

Mozzi’s Pizza had been operating with deck ovens for over 40 years. While these ovens had served them well, they posed several challenges:

- Slow Cooking Times: Large orders were difficult to fulfill quickly.

- Labor-Intensive: Employees needed to constantly monitor the ovens.

- Inconsistency: Variations in temperature and baking led to inconsistent pizza quality.

- Limited Throughput: With growing demand, deck ovens were struggling to keep up.

- Difficult Training: New hires found it challenging to master deck oven baking.

Mozzi’s knew they needed a change. Enter XLT Conveyor Ovens.

Solution: Upgrading to XLT Conveyor Ovens & Hoods

Mozzi’s Pizza partnered with C&T Design and Equipment for the installation and transition. Deven Kaufman, who led the installation process, described the transformation:

“To see the results from what they used to have—how complicated it was—to what they have now, it makes everything so simple. The production has been great for them.”

— Deven Kaufman, C&T Design

Mozzi’s first location to upgrade quickly saw significant improvements. The consistent heat distribution and automated conveyor system allowed the kitchen staff to focus on other tasks without worrying about uneven baking.

Results: A Faster, More Efficient Kitchen

1. Increased Production & Speed

The switch to XLT Ovens immediately boosted productivity. Mozzi’s went from struggling with large orders to fulfilling 109 pizzas in under an hour—a feat impossible with their old deck ovens.

“If [Mozzi’s] didn’t have the XLT ovens, they would have had to decline that order.”

— Chuck Freer, XLT Account Executive

Mozzi’s Pizza can now serve more customers faster, which has led to higher revenue and greater customer satisfaction.

2. Consistency in Every Slice

Kitchen staff, including long-time employees like Brian, immediately noticed a difference in the quality of the food.

“Before, nothing ever came out of those [old ovens] done. Now, everything comes out consistent. I don’t even have to babysit the pizzas anymore.”

— Bryan, Kitchen Manager (31+ years at Mozzi’s)

The improved heat control ensures every pizza, every cookie, and every dish is cooked to perfection—regardless of who is operating the ovens.

3. Reduced Labor Costs & Training Time

With deck ovens, training new employees was a challenge. The transition to XLT Conveyor Ovens has streamlined the process, making it easier to train new hires and reduce labor dependency.

“Nobody wants to get burnt [by deck ovens]. These new ovens will make it easier for employees to learn and operate.”

— Rob, Mozzi’s Location Owner (42 years in the business)

4. Increased Takeout & Delivery Capabilities

Mozzi’s Pizza also expanded their online delivery services with platforms like DoorDash and GrubHub—something they hesitated to do before due to slow oven speeds.

“We were worried we couldn’t keep up before. Now, with XLT ovens, our pizzas come out faster than the DoorDash driver can get here!”

— Tyler, General Manager

With XLT’s faster cook times, Mozzi’s is now able to accommodate the growing demand for delivery and takeout orders while maintaining quality.

Future Expansion: More Locations Making the Switch

Encouraged by the success of their first upgrade, Mozzi’s Pizza is now planning to outfit all of their locations with XLT Ovens and Hoods. Locations still operating with deck ovens will soon undergo similar transformations.

Deven Kaufman, overseeing the installations, shared his enthusiasm:

“We’re replacing the old deck ovens with XLT triple-stack conveyor ovens and hoods. The short lead time and efficient installation mean they’ll be up and running in no time.”

Mozzi’s commitment to quality, efficiency, and innovation ensures they remain a favorite in the Indianapolis area for years to come.

Conclusion: Why Mozzi’s Pizza Loves XLT Ovens

Mozzi’s Pizza’s transition to XLT Conveyor Ovens has revolutionized their operations. By switching to XLT, they have:

- Increased Speed & Productivity

- Improved Consistency & Quality

- Reduced Labor Costs & Training Time

- Expanded Delivery & Takeout Services

- Future-Proofed Their Business for Growth

If you’re looking to enhance your restaurant’s efficiency, consistency, and profitability, it’s time to Make the Switch to XLT Ovens.

Interested in upgrading your ovens? Contact us today to learn more about how XLT can help your business grow.