XLT is thrilled to announce a significant expansion of our distribution network with the addition of The Yes Group as our new partner serving North Dakota, South Dakota, Minnesota, and Wisconsin. This collaboration marks an important step forward in our commitment to providing unparalleled service and accessibility to our industry-leading conveyor ovens and hood ventilation systems.

One of the primary reasons we selected The Yes Group is their impressive ability to stock products for immediate access and delivery. With multiple warehouses located strategically throughout North Dakota, South Dakota, Minnesota, and Wisconsin, they ensure that our customers can get their hands on the XLT equipment when they need it, reducing custom order wait times. This efficient stocking capability means that whether you’re in the middle of a busy season or preparing for an upgrade, The Yes Group has the inventory on hand to meet your demands quickly and reliably.

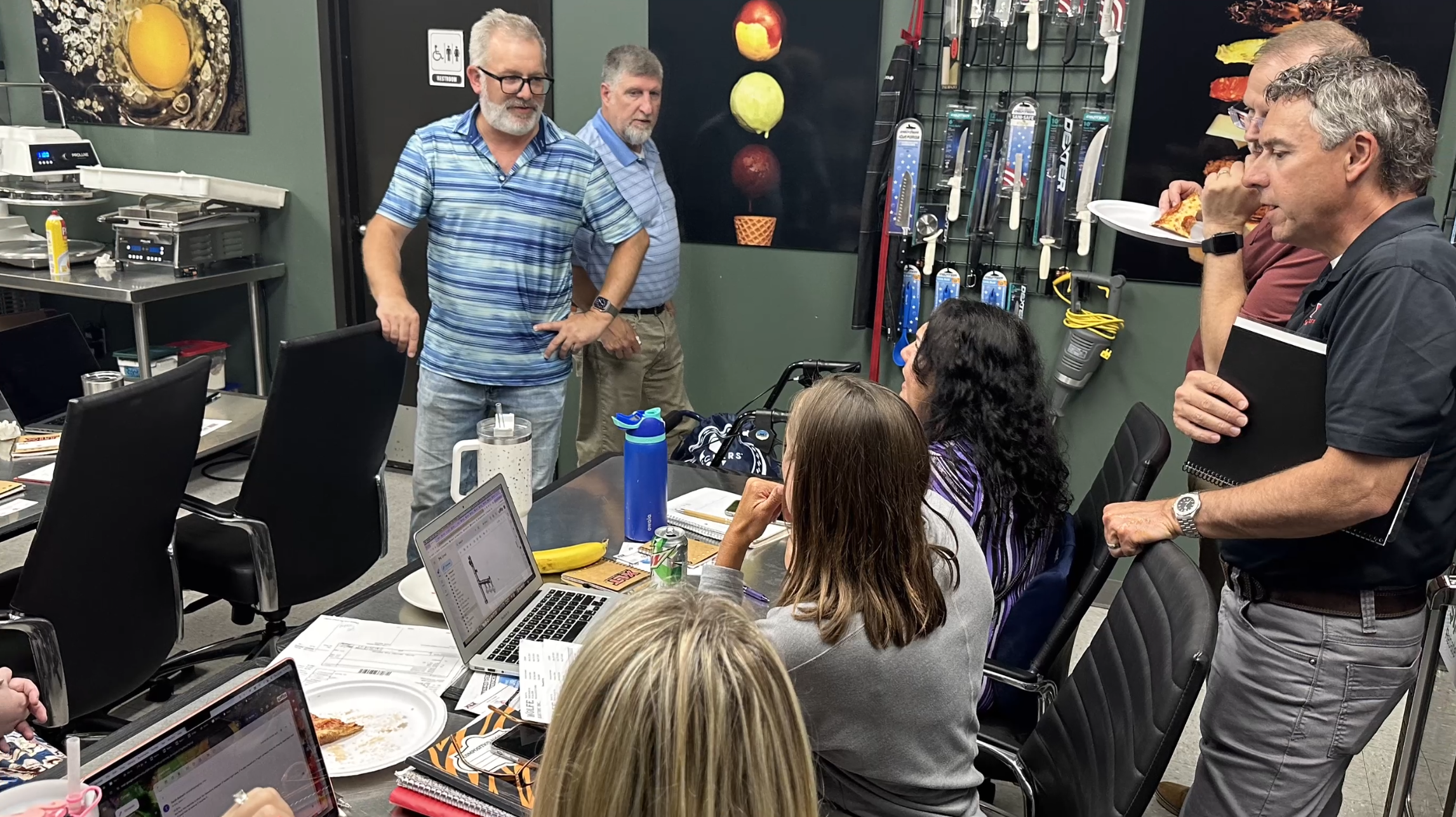

In addition to their extensive warehousing capabilities, The Yes Group boasts two test kitchens in the region, allowing customers and prospects to bake their products closer to home without the need to travel to XLT headquarters in Wichita, KS. These local test kitchens provide a unique opportunity for you to experience the quality and performance of XLT ovens firsthand, making the decision-making process that much easier.

But that’s not all. The Yes Group is a full-service distributor, offering comprehensive installation services, warranty support, and a wide range of service parts to keep your kitchen running smoothly. The entire Yes Group team is dedicated to ensuring you receive the highest level of service.

We are confident that this partnership with The Yes Group will greatly enhance your XLT experience by bringing our innovative solutions closer to you while providing the local expertise that understands the unique needs of your business.

For more information or to get in touch with The Yes Group, please contact them at:

- sales@theyesgroup.com

- (651) 452-9889

- (414) 326-3600

- www.TheYesGroup.com

And don’t forget to like, follow, and share their information to stay updated on all things XLT in North Dakota, South Dakota, Minnesota, and Wisconsin!